Spray Dryers

New AVM offers customized spray dryers, mini spray dryers and spray drying systems in different configurations. The dryers are made to convert liquid solutions/suspensions/slurry/emulsions to powder, granules or agglomerates. The gross advantage of spray dryers is consistent product quality with better control on product parameters like product moisture, bulk density, particle size, dispersion, flow ability etc.

Air Flow Pattern Configurations :

- Co- current

- Counter-current

- Mixed flow

Combination of Systems Configurations:

Two Stage Spray Dryer - spray dryers followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying.

Three Stage Spray Dryer - spray dryers with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates.

Liquid Atomizer Configurations:

Single Fluid Nozzle Atomizers.

The liquid feed is atomized into spray droplets by using pressure energy.

Two Fluid Nozzle Atomizers.

The liquid feed is atomized into spray droplets by using energy of secondary fluid like Compressed Air, Nitrogen etc.

Rotary Disc Atomizers / Rotary Atomizers.

In Rotary disc Atomizers, the kinetic energy of wheel is used for atomization.

Air Heating System Configurations :

- Direct Fired / Indirect Fired Air Heaters: using Liquid / Gaseous Fuels.

- Direct / Indirect Fired Air Heaters: using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc.

- Indirect Air Heaters: Using Steam / Hot Oil / Thermic Fluid

- Electric Air Heaters: using electricity.

Product / Fines Recovery System Configurations:

Cyclone Separators – Mono, Twin, Quadruple, Multi etc.

Bag Filters – Reverse Pulsejet, Mechanical shaking etc.

Wet Scrubbers – Direct Contact Ventury, Adjustable Ventury, Packed scrubbers etc..

Optional Features Configurations:

- Rotating air brooms with dehumidified air.

- Roof cooling. Rotary atomizer Cooling. Nozzle Lance Cooling.

- Online Dosing & Blending system.

- Product Cooling & conveying system.

- Online gas induction system in feed liquid.

- Feed Preparation system.

- Closed Loop Systems / Self Inertized Systems with inert gas as process drying media.

- Solvent Recovery Systems.

- Cleaning in Place Systems.

- Heat Recovery Systems.

- CGMP Construction.

- Safety accessories like Explosion vents with pressure shock resistant design for equipments, explosion de-coupling, Mechanical flame diverter, Vacuum breaker, Fire fighting system

- Computerized control system through PLC / DCS & SCADA.

It's includes:

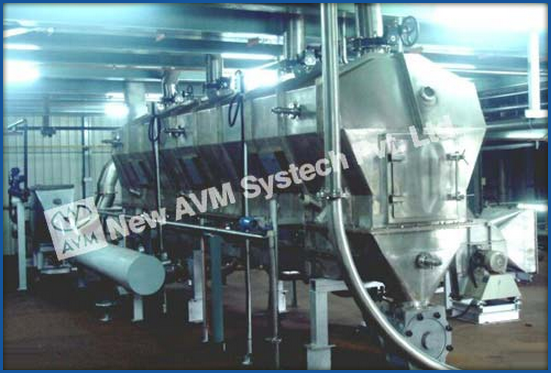

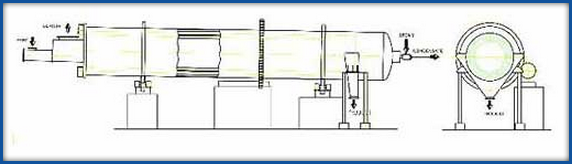

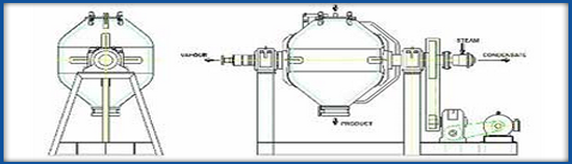

Two Stage Spray Dryer

This two stage spray dryer is equipped with fluid bed dryer for drying products which require longer residence time & product conditioning post drying.

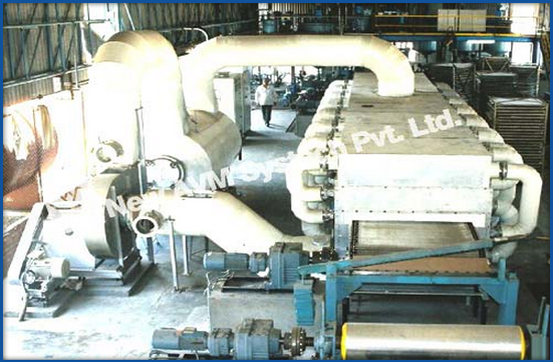

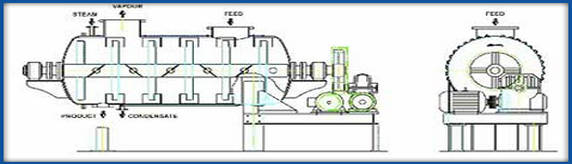

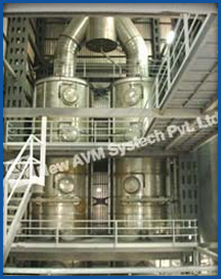

Three Stage Spray Dryer

This three stage spray dryer has an internal fluid bed equipped with fluid bed dryer for producing free agglomerates.